Geoff's Journal..

- Details

- Written by: Geoff Colmes

In 2002 my friend James W Hall mentioned he and his wife would be selling their long-time home in Key Largo and moving to Coral Gables. Living in both the Gables and the Western North Carolina mountains wasn't going to give him as much time to use his new skiff, and he asked me if I was interested in buying it. James knew that I already owned a similar but older 1998 Whip, but he made it easy for me, so I sold my older Whipray to my friend Capt. Andy Putetti and purchased Halls newer model. I promised my friend I would take good care of her, and I kept my promise.

In 2002 my friend James W Hall mentioned he and his wife would be selling their long-time home in Key Largo and moving to Coral Gables. Living in both the Gables and the Western North Carolina mountains wasn't going to give him as much time to use his new skiff, and he asked me if I was interested in buying it. James knew that I already owned a similar but older 1998 Whip, but he made it easy for me, so I sold my older Whipray to my friend Capt. Andy Putetti and purchased Halls newer model. I promised my friend I would take good care of her, and I kept my promise.

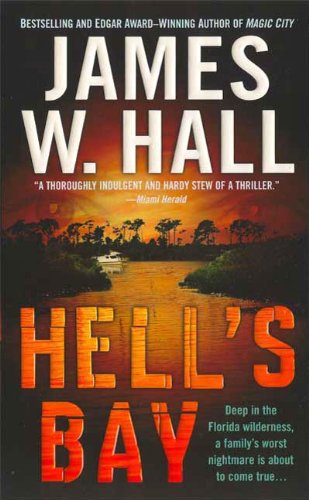

Almost twenty years later, I'm still guiding, and Hall is still writing great novels. His old Whipray has seen a lot of use; from outfitted camping trips in the Everglades, to Mothership based trips aboard 'Fishabout' in the Glades, Marquesas and Content Keys. She's been wedged (literally stuck) between trees in spider infested mangrove tunnels, battered by numerous tropical depressions in the Marquesas and strong Winter cold fronts in the Glades. The skiff has slid off my trailer on top of a boat ramp, has had numerous Burmese Python encounters and large tarpon have jumped and landed in her. Aside from all the amazing and memorable fishing moments with family, friends and fishing clients, there was the encounter at Cardiac Bay involving the Everglades Park Rangers while on our Mothership with none other than James W Hall onboard researching his 2008 novel ‘Hells Bay.’

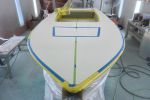

This past summer I contemplated selling her and buying a new 2020 model, however, my potential buyers’ yacht davit was underrated for the actual weight of the skiff. The gentleman understandably bowed out of the arrangement, and I'm glad he did. For those of you that think your ultra light Whipray with the engine and hardware only weighs 750 pounds or so, take her to your nearby weigh station and you’ll see it’s closer to 1000 lbs. "wet." Skiff manufacturers (with a few exceptions) are inaccurate if not deceptive when publishing weight and draft specs; fishing guides and anglers have always been optimistic and willing to believe they have the lightest and the shallowest draft skiff on the planet. Thankfully, I decided not to sell her and instead looked for the best in the business to do a complete restoration. After some research, and a few dead ends, I found Glasser Boatworks in Rockledge, FL. Glasser agreed to take on the job and decided to keep and restore the original yellow gelcoat - which looks better now than when she came out of the Hells Bay factory in 2002. Most of Glassers work however, was to be done above the hull.

This past summer I contemplated selling her and buying a new 2020 model, however, my potential buyers’ yacht davit was underrated for the actual weight of the skiff. The gentleman understandably bowed out of the arrangement, and I'm glad he did. For those of you that think your ultra light Whipray with the engine and hardware only weighs 750 pounds or so, take her to your nearby weigh station and you’ll see it’s closer to 1000 lbs. "wet." Skiff manufacturers (with a few exceptions) are inaccurate if not deceptive when publishing weight and draft specs; fishing guides and anglers have always been optimistic and willing to believe they have the lightest and the shallowest draft skiff on the planet. Thankfully, I decided not to sell her and instead looked for the best in the business to do a complete restoration. After some research, and a few dead ends, I found Glasser Boatworks in Rockledge, FL. Glasser agreed to take on the job and decided to keep and restore the original yellow gelcoat - which looks better now than when she came out of the Hells Bay factory in 2002. Most of Glassers work however, was to be done above the hull.

Jonathan Glasser seamlessly handled the entire project - the complete restoration of the skiff. Aside from his work on the hull, hatches, hardware and deck, he oversaw the custom aluminum fabrication including a new and larger capacity fuel tank, console rail ‘branch deflector,’ and bow and stern platforms.

Jonathan Glasser seamlessly handled the entire project - the complete restoration of the skiff. Aside from his work on the hull, hatches, hardware and deck, he oversaw the custom aluminum fabrication including a new and larger capacity fuel tank, console rail ‘branch deflector,’ and bow and stern platforms.

Glasser arranged the purchase of my new Mercury 60R from Mullis Marine, and oversaw the custom SeaDek installation and the new rigging by Brian Floyd, (Floyd Skiffs). I can’t say enough about Jonathan’s work ethic and attention to detail from the finish down to the last nut and bolt; this was a fun project, and he was a pleasure to work with.

Deck and Console

Original hull gelcoat restoration, new cockpit and upper deck non-skid surface, filled numerous holes, refinished console, filled more holes.

Hatches and Lockers

Forward locker hatch and gutters had to be cut out to install the new 20 gallon fuel tank. The battery was moved to the forward locker from the stern, and offset to the port side to compensate for the starboard side-console. A shelf was fabricated to allow level storage in the bow locker. The additional weight in the bow more than compensated for the extra 50 extra pounds of the new Mercury 60R. Both bow and stern hatches and lockers were completely refinished.

Hardware, Electronics and Rigging

Custom fabricated 20 gallon fuel tank, poling platform, bow casting platform and what I refer to as a branch deflector on the console. A new Mercury 60R, along with new rigging. Every hose, nut, bolt and latch was either refurbished or replaced, and yep, more holes filled. Black SeaDek was installed on the side rod storage and camel Seadek on the bow and stern towers. Custom cut black SeaDek was used instead of traditional gaskets on the hatches.

Subcategories

Page 4 of 4